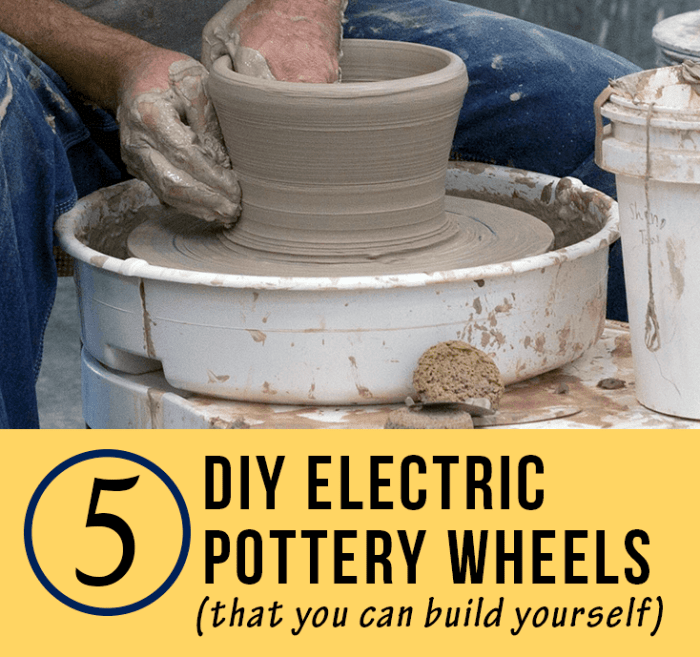

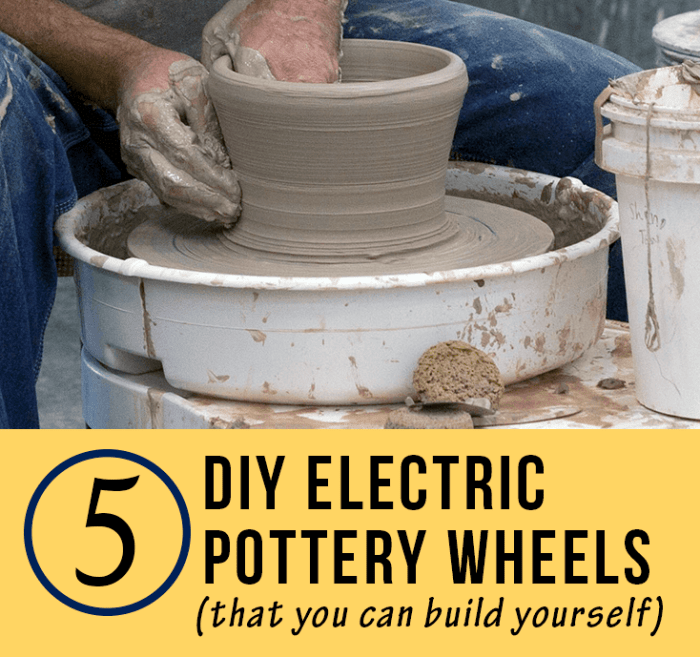

Diy potters wheel – DIY Potter’s Wheel: Build Your Own Ceramic Studio – The allure of crafting with clay has captivated artists and enthusiasts for centuries. But owning a pottery wheel can be a significant investment. Fortunately, the DIY spirit thrives in the world of ceramics, offering a path to create your own pottery wheel from readily available materials. This guide delves into the fascinating world of DIY pottery wheel construction, empowering you to build a functional and personalized studio centerpiece.

From understanding the basic components of a pottery wheel to selecting the right materials and tools, we’ll navigate each step of the process with clear s and practical advice. Whether you’re a seasoned potter or a curious beginner, this guide will equip you with the knowledge and confidence to embark on your own DIY pottery wheel journey.

Understanding the Basics of Pottery Wheels

A pottery wheel is an essential tool for shaping clay into various forms. It provides a rotating platform that allows potters to manipulate clay with their hands, creating symmetrical and balanced pieces. There are two primary types of pottery wheels, each with its own advantages and disadvantages: kick wheels and electric wheels.

Types of Pottery Wheels

There are two main types of pottery wheels: kick wheels and electric wheels.

- Kick Wheels: Kick wheels are powered by the potter’s foot. They are typically made of wood and metal and are often considered more traditional and less expensive than electric wheels. Kick wheels require more physical effort to operate, but they also provide greater control over the speed and direction of rotation.

- Electric Wheels: Electric wheels are powered by an electric motor and offer a more convenient and consistent experience. They are often preferred by potters who work with large amounts of clay or who require precise control over the speed and direction of rotation. Electric wheels are also available in a wide range of sizes and features, from basic models to advanced ones with variable speed controls and foot pedals.

Key Components of a Pottery Wheel

The key components of a pottery wheel include:

- Wheel Head: The wheel head is the rotating platform where the clay is placed. It is typically made of wood or metal and is attached to the wheel’s base.

- Wheel Base: The wheel base is the stationary part of the pottery wheel that supports the wheel head. It can be made of various materials, including wood, metal, or concrete.

- Spindle: The spindle is a vertical shaft that connects the wheel head to the wheel base. It allows the wheel head to rotate smoothly.

- Bearing: The bearing is a component that supports the spindle and reduces friction during rotation.

- Foot Pedal (for Kick Wheels): The foot pedal is used to control the speed and direction of rotation on a kick wheel.

- Motor and Speed Control (for Electric Wheels): The motor provides power to the electric wheel, and the speed control allows the potter to adjust the speed of rotation.

Safety Tips for Using a Pottery Wheel

It is essential to follow safety precautions when using a pottery wheel to avoid injuries.

- Wear Protective Gear: Always wear a dust mask to protect yourself from inhaling clay dust. Safety glasses are also recommended to shield your eyes from flying debris.

- Keep Your Workspace Clean: A clean workspace reduces the risk of accidents and helps prevent clay dust from accumulating.

- Use a Sturdy Workbench: The pottery wheel should be placed on a stable and sturdy workbench to prevent it from tipping over.

- Avoid Distractions: Distractions can lead to accidents, so focus on your work and avoid talking or listening to music while using the pottery wheel.

- Be Aware of Your Surroundings: Pay attention to your surroundings and make sure there are no obstacles in your way.

- Start Slowly and Gradually Increase Speed: Begin with a slow rotation speed and gradually increase it as you become more comfortable.

- Stop the Wheel Before Removing Clay: Always stop the wheel before removing the clay from the wheel head to prevent injury.

Choosing the Right Materials: Diy Potters Wheel

The materials you choose for your DIY pottery wheel will determine its durability, performance, and overall cost. It’s important to consider your design, budget, and desired features before making your selections.

You’ll need to choose materials for the wheel’s base, turntable, and motor.

Wood

Wood is a popular choice for DIY pottery wheels due to its affordability, ease of working, and natural beauty. When selecting wood, consider its strength, stability, and resistance to moisture.

Here are some tips for choosing the right wood for your pottery wheel:

* Hardwoods like oak, maple, and cherry are strong and durable, making them ideal for the base and turntable. They also have a beautiful grain pattern that adds to the aesthetic appeal of the wheel.

* Softwoods like pine and fir are less expensive but are not as strong or durable as hardwoods. They may be suitable for less demanding applications, such as the frame or support structure.

* Plywood is a good option for the base or turntable, as it is strong and stable. It is also relatively inexpensive and easy to work with.

* Reclaimed wood can be a sustainable and cost-effective choice for your pottery wheel. Look for hardwoods that are free from rot, cracks, or insect damage.

Metal

Metal is a durable and long-lasting material for pottery wheels, but it can be more challenging to work with than wood. When selecting metal, consider its strength, weight, and corrosion resistance.

Here are some tips for choosing the right metal for your pottery wheel:

* Steel is a strong and durable metal that is often used for the base, turntable, and motor mount. It is also relatively inexpensive.

* Aluminum is a lightweight and corrosion-resistant metal that is often used for the turntable. It is also easy to work with.

* Stainless steel is a corrosion-resistant metal that is often used for the base and turntable. It is more expensive than steel or aluminum, but it will last longer.

* Reclaimed metal can be a sustainable and cost-effective choice for your pottery wheel. Look for metal that is free from rust, corrosion, or damage.

Other Materials, Diy potters wheel

In addition to wood and metal, you may also need other materials for your DIY pottery wheel, such as:

* Bearings are essential for the smooth rotation of the turntable. Choose bearings that are appropriate for the weight of the turntable and the speed at which you plan to use the wheel.

* Fasteners such as screws, bolts, and nuts are needed to assemble the various components of the pottery wheel. Use high-quality fasteners that are appropriate for the materials you are using.

* Glue can be used to bond wood components or to secure metal parts. Use a strong and durable glue that is appropriate for the materials you are using.

Advantages and Disadvantages of Reclaimed Materials

Reclaimed materials offer several advantages for DIY pottery wheel construction:

* Sustainability: Using reclaimed materials reduces the need for new resources, which is better for the environment.

* Cost-effectiveness: Reclaimed materials are often available at a lower cost than new materials.

* Uniqueness: Reclaimed materials can add a unique character to your pottery wheel.

However, there are also some disadvantages to using reclaimed materials:

* Availability: Finding the right reclaimed materials can be challenging, especially if you have specific requirements.

* Condition: Reclaimed materials may be damaged or require additional processing before they can be used.

* Safety: Reclaimed materials may contain harmful substances, such as lead paint or asbestos. It is important to inspect them carefully before using them.

Troubleshooting and Maintenance

Even the most meticulously crafted DIY pottery wheel can encounter issues during its construction or use. Understanding common problems and their solutions is crucial for ensuring a smooth and successful pottery experience. Regular maintenance practices can also extend the lifespan of your wheel and prevent future complications.

Troubleshooting Common Issues

It is essential to identify and address potential problems promptly to prevent further damage or inconvenience. Common issues that may arise during the construction or use of a DIY pottery wheel are discussed below.

- Wobbly Wheel Head: A wobbly wheel head can lead to uneven clay distribution and make throwing difficult. This issue often arises due to loose bolts, misaligned bearings, or uneven weight distribution on the wheel head.

- Uneven Rotation: If the wheel spins erratically or inconsistently, it could be caused by a faulty motor, worn bearings, or a poorly balanced wheel head.

- Excessive Noise: A loud, grinding sound during wheel operation often indicates worn bearings, a loose belt, or a problem with the motor.

- Wheel Head Sticking: The wheel head might stick or become difficult to rotate due to friction caused by worn bearings, a buildup of clay residue, or a tight belt.

- Motor Overheating: Excessive motor heat can result from a malfunctioning motor, a clogged ventilation system, or overloading the motor with too much clay.

Troubleshooting Tips

The following tips can help you resolve common issues and ensure your DIY pottery wheel operates smoothly.

- Check for Loose Bolts: Regularly tighten all bolts and screws connecting the wheel head, bearings, and other components.

- Lubricate Bearings: Apply a light layer of grease to the wheel head bearings to reduce friction and ensure smooth rotation.

- Balance the Wheel Head: Ensure the wheel head is evenly balanced to prevent wobbling. You can achieve this by adjusting the weight distribution or adding counterweights.

- Clean Clay Residue: Regularly clean the wheel head and surrounding areas to remove any accumulated clay residue that could hinder rotation.

- Inspect the Motor: If the motor overheats, check for any obstructions in the ventilation system or ensure it is not overloaded.

- Adjust the Belt Tension: A loose belt can cause slippage and noise, while a tight belt can strain the motor and bearings. Adjust the belt tension according to the manufacturer’s recommendations.

- Replace Worn Parts: If you identify worn bearings, belts, or other components, replace them with new ones.

Maintenance Practices

Regular maintenance is crucial for ensuring the longevity of your DIY pottery wheel.

- Clean Regularly: Wipe down the wheel head, base, and motor after each use to remove any clay residue or spills.

- Lubricate Bearings: Lubricate the wheel head bearings with a light layer of grease every few weeks or as needed.

- Inspect Belts: Regularly check the belt for wear and tear. Replace it if it shows signs of cracking, fraying, or excessive stretching.

- Check Motor: Ensure the motor is clean and well-ventilated. If it overheats, investigate the cause and address it promptly.

- Store Properly: When not in use, cover the wheel head and base with a dust cover to protect them from dirt and debris.

Inspiring DIY Pottery Wheel Projects

The world of DIY pottery wheels is brimming with creativity and ingenuity. From simple, hand-cranked designs to more elaborate, electric-powered models, people are constantly pushing the boundaries of what’s possible. These projects are not only a testament to the human spirit of innovation but also a reflection of the passion for pottery and the desire to create beautiful objects.

Examples of Creative DIY Pottery Wheel Designs

There are numerous examples of creative DIY pottery wheel designs that demonstrate the boundless possibilities of this craft. These projects often incorporate unique materials and innovative mechanisms, making them both functional and aesthetically pleasing.

- The “Wheel of Fortune”: This design utilizes a repurposed bicycle wheel as the base, with a simple, hand-cranked mechanism attached to the hub. The wheel’s natural rotation provides a smooth and consistent spinning motion, making it ideal for beginners.

- The “Upcycled Motor Wheel”: This project repurposes an old washing machine motor to power the wheel, offering a more powerful and efficient spinning experience. The motor is typically mounted on a sturdy wooden frame, with a clay-forming head attached to the rotating shaft.

- The “3D-Printed Wheel”: This innovative design utilizes 3D printing technology to create custom-designed components for the wheel, allowing for greater precision and customization. The printed parts can be assembled to form a sturdy and functional wheel, offering a modern twist on traditional designs.

Online Communities and Resources

The internet is a treasure trove of information and inspiration for DIY pottery wheel enthusiasts. Numerous online communities and resources offer guidance, support, and inspiration for those interested in building their own wheels.

- Reddit’s “r/Pottery”: This subreddit is a vibrant online community where potters of all levels share their work, tips, and advice. You can find numerous discussions and projects related to DIY pottery wheels, as well as helpful resources and tutorials.

- The “DIY Pottery Wheel Forum”: This dedicated forum provides a platform for DIY enthusiasts to connect, share their experiences, and seek advice from experienced builders. The forum offers a wealth of information, including design plans, construction techniques, and troubleshooting tips.

- YouTube Channels: Several YouTube channels are dedicated to DIY pottery wheels, featuring tutorials, reviews, and demonstrations. These channels offer a visual learning experience, allowing you to see the process of building a wheel from start to finish.

Inspiring Stories of DIY Pottery Wheel Builders

The stories of individuals who have successfully built and used DIY pottery wheels are a source of inspiration and encouragement. These individuals have overcome challenges, embraced creativity, and ultimately achieved their goal of creating their own pottery wheels.

- The “Backyard Potter”: This individual, inspired by a passion for pottery and a limited budget, decided to build their own wheel using salvaged materials and basic tools. Their journey, documented on a blog and social media, has inspired countless others to pursue their own DIY pottery projects.

- The “Wheelwright”: This individual, with a background in engineering and a love for pottery, designed and built a highly sophisticated DIY pottery wheel using advanced materials and precision tools. Their project, showcased at local craft fairs and exhibitions, has demonstrated the potential for innovative and high-quality DIY pottery wheels.

Building your own pottery wheel is a rewarding experience that combines creativity, craftsmanship, and the joy of bringing a unique project to life. It’s a journey that empowers you to personalize your studio space and unlock a world of artistic possibilities. So, gather your tools, embrace the process, and let your imagination guide you as you create your own DIY pottery wheel masterpiece.

Building a DIY potter’s wheel can be a rewarding project, allowing you to create beautiful ceramics from scratch. While you’re working on your wheel, you might also consider improving the comfort of your workspace. Installing a mini-split AC unit can be a great way to regulate the temperature, and you can find helpful instructions for doing it yourself at installing a mini split diy.

Once your workspace is comfortable, you can focus on perfecting your pottery skills and creating stunning pieces.